Hydrogas

Fostering energy efficiency and GHG-emissions savings through the recuperation of residual gases in the aluminium recycling industry

Project Summary

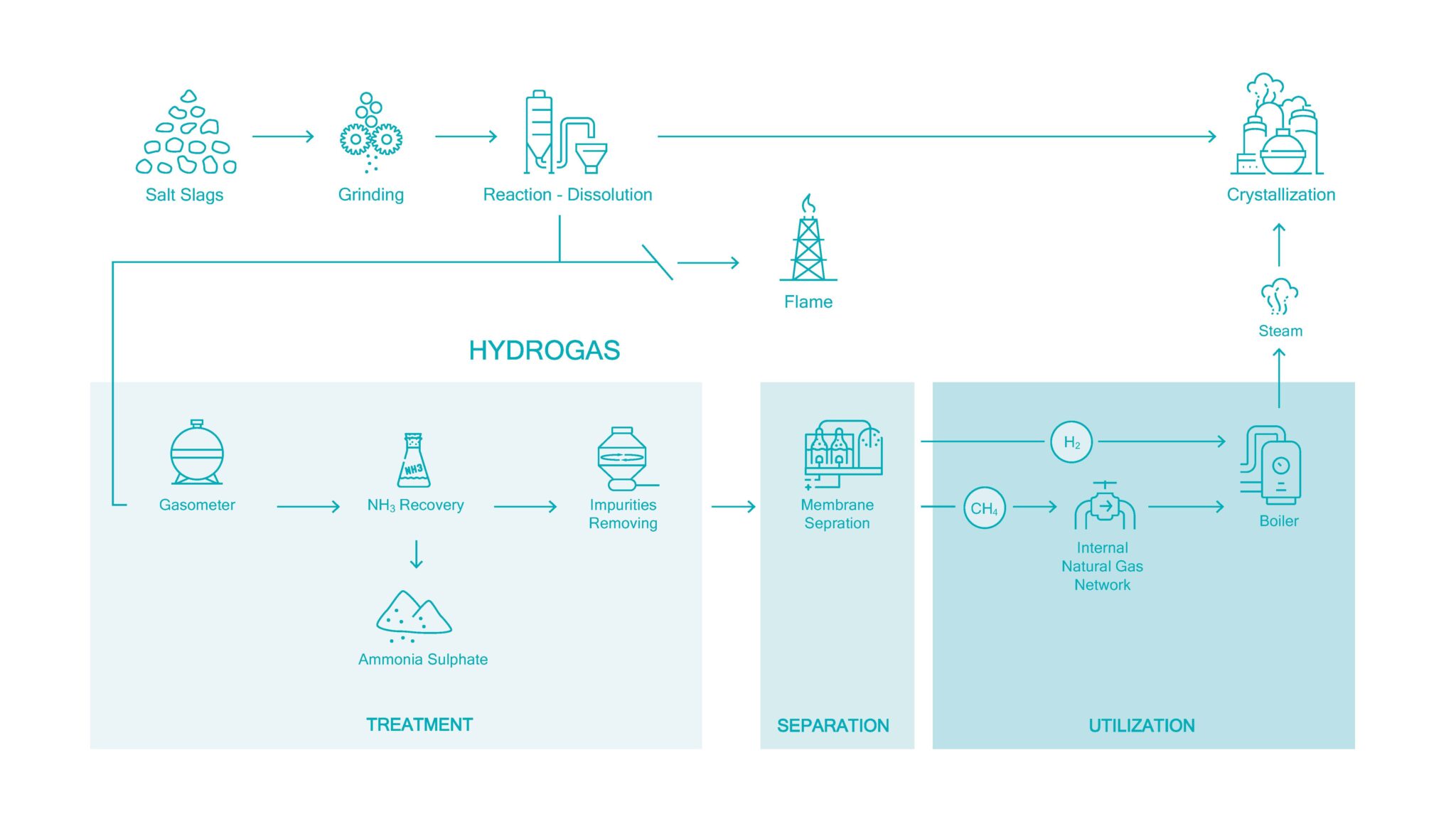

The LIFE HYDROGAS project aims to be the first one to implement an innovative solution that is capable of stabilizing the waste gas stream (Hydrogas) from the aluminium salt slag recycling process, cleaning it and separating flows in such a way as to obtain separate streams of H2 and CH4 of high purity which are used as alternative fuels to natural gas. A novel membrane technology will be used to obtain a high purity H2 stream on the one hand and a CH4-rich stream on the other hand. Given the complexity of the stream to be treated and burned, it is necessary to include a cleaning stage to remove certain compounds (such as siloxanes, H2S, and VOCs) in the separation process head. For this purpose, the integration of various purification techniques, available in the market, will be carried out, which will allow reducing the impurities in the gas to permissible limits so that they can subsequently be separated and utilized. Furthermore, the NH3 present in gas stream is recovered for subsequent sale on the market. The physical fluctuations of the Hydrogas stream will be stabilized thanks to the implementation of damping technologies that will ensure a continuous feed flow. The LIFE HYDROGAS projects successful installation and operation of a waste gas stream treatment and valorisation plant for energy purposes will reduce the environmental footprint of the salt slag recycling process by 36 %, reducing the energy consumption of 17,9 GWh/year and the reduction of 3.619 ton of CO2eq/year.

Coordinator Contact details

Coordinating Beneficiary:

BEFESA ALUMINIO SLU

Address:

Crta. Luchana Asúa, 13 48950, Erandio (Vizcaya), SPAIN

Contact person:

Jessica Montero

Administrative Data

Reference:

LIFE23-CCM-ES-LIFE-HYDROGAS/101157282

Total Eligible Budget:

3.734.385€

EU Contibution:

2.240.631€

Objective

The main objective of the project is to implement an innovative solution capable of stabilizing the flow of residual Hydrogas, conditioning it, and separating these streams in such a way as to obtain high-purity H₂ and CH₄ streams. These will be used as alternative fuels to natural gas in steam boilers.

Expected results

Aligned with the main objective, the following expected results are proposed

Technical

Environmental

Socioeconomical

Act as a catalyst for the development of circular business models, fostering synergies between different industries, generating employment, facilitating knowledge exchange, and promoting social integration. These impacts collectively contribute to a more sustainable and prosperous future for the region, serving as a model for sustainable industrial practices.